Strategic planning – flexible implementation

Due to the new organisational structure and the move into a new office building the HORSCH purchasing department now can work in an even more agile and flexible way. This is very helpful especially with regard to the conditions of the pandemic and the resulting price increases at the market. Dr. Johann Neidl, head of purchasing and digitalization, tells us more.

terraHORSCH: What did the move bring about? What is working in the purchasing department at HORSCH like now?

Dr. Johann Neidl: The move had very positive effects. Due to the new surroundings, we achieve an even tighter interaction between the different purchasing teams – operative purchasing, project purchasing etc. Our method of working has already been very agile and flexible, and this was even reinforced by the spatial concept and the modification of our method of working. The whole team is located on one floor. Short distances, optimum flow of information and communication support a quick co-ordination and reaction to market changes.

If necessary, the project purchasers temporarily move in with R & D. Thus, we make sure that during the period when initial decisions with regard to the product are taken there is a close co-ordination between the engineers and the purchasers. This concentrated combination of know-how guarantees that all necessary product information is handled at the right time. Due to the changing workplaces the interdisciplinary exchange, agility and flexibility are influenced positively. The distances are short, you get important information more quickly and solutions can be found much faster.

The objective of moving from the old into the new building also was to make ideas and information flow more quickly and better between the colleagues. The rooms were designed accordingly. There is a communication zone where you can meet for an exchange. This, too, was the idea behind the spatial concept: to set up something new where people can meet, where ideas and concepts can develop and where solutions can be found. This method of working creates new creative approaches that are necessary to continuously increase efficiency and performance.

terraHORSCH: An interesting approach to push creative approaches in purchasing, to strike new paths.

Dr. Johann Neidl: Recurring tasks as well as non-creative tasks, e.g. component orders which according to fixed rules are classified as “can be ordered automatically” or structured analysis of thousands of parts – they can and will be carried out to an increasing extent by intelligent systems respectively algorithms in the future. This means that we want to achieve a higher automation in the individual purchasing teams. Thus, the employees can spend more time on other, value-adding tasks like the close co-operation and the exchange with suppliers and partners. I think about 30 % of the scheduling tasks can be carried out automatedly by AI systems according to certain rules. Our objective is not to cut jobs, but to shift the tasks to facilitate everyday work. We want to achieve a balance between what AI (Artificial Intelligence) can do and the value-adding tasks, i.e. the ideas behind it, relationships with the suppliers, human relations – everything AI quite simply cannot do.

terraHORSCH: How did the new organisational structure in the company improve the situation in the purchasing department?

Dr. Johann Neidl: A good network within the company is very important. People have to co-operate closely and discuss with the right people at an early stage to guarantee that if the worst comes to the worst we can react to changes in due time. The distances are shorter, and we can work in a more agile way as the hierarchies are flatter or do not exist at all. The new network structure and the move into the new building definitely had an effect on co-operation. But one thing is essential: It is not only important to change the structure, but also to qualify the employees to work in the new surroundings. In my opinion, this is the most important aspect by far!

terraHORSCH: What about the global purchasing organisation at HORSCH?

Dr. Johann Neidl: Our motto is to provide as many regulations as necessary centrally, but as few as possible. Local flexibility and speed have to be taken into consideration. However, we, of course, still try to use suppliers that are active on a global scale. If we co-operate for example with a supplier of hydraulic components who goes global, we certainly recommend to our branches to purchase the relevant components from him on site. With regard to methods and tools, e.g. SAP systems, we want to realise a global orientation so that everyone works with the same standard in order to prevent interface and information inconsistencies. Moreover, we try to push the standardisation on the component level worldwide. Thus, the branches can support each other in case of delivery difficulties of a supplier. The focus particularly is on the more complex and cost-intensive components like cylinders, hydraulics and electronics. In this respect we attach great important to realise maximum standardization. This, of course, facilitates the security of supply and the parts service.

terraHORSCH: How does the current delivery and price situation affect the HORSCH purchasing department?

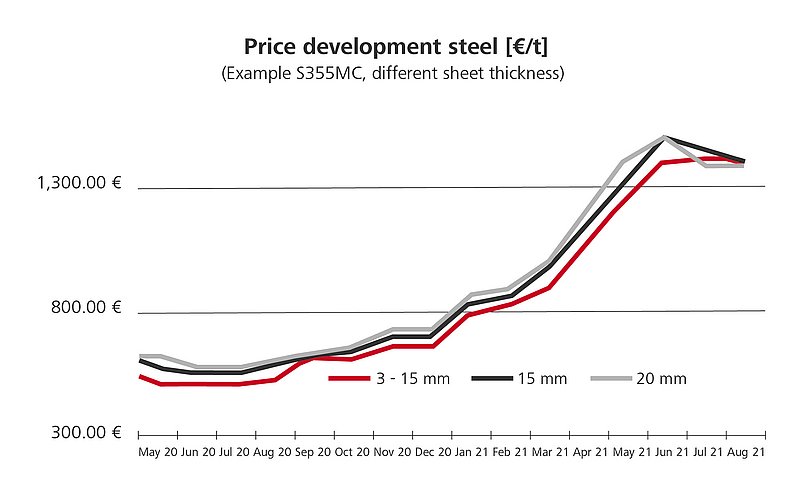

Dr. Johann Neidl: HORSCH, too, feels the extreme price increases, material bottle necks and delays in the delivery chain. The prices continue to be on a high level, especially in the electronic sector and the supply becomes more and more critical. We partly have to buy components from brokers which cost 10 to 30 times as much compared to the standard price to be able to go on producing at all.

Since about two years, production has been going full speed. Because of the Covid 19 situation and the supply bottlenecks it is a financial and a personal major effort to keep it running. When the assembly lines at other companies stopped or employees had to work short time, we still were able to go on. In this respect, too, the purchasing department contributed a great deal to guarantee the material supply not only on a short-term basis but also in the medium and in the long run due to the good, co-ordinated internal co-operation but also due to the co-operation with the suppliers. Our extremely fair partnership with the suppliers, of course, is helpful.

terraHORSCH: What does this fair partnership look like?

Dr. Johann Neidl: A fair co-operation is very important. We have to cope with this currently difficult time together. This is why we attach great importance to long-term partnerships. Our objective is to involve our suppliers early and comprehensively and to provide them with the necessary information, e.g. forecast figures, so that they can plan accordingly and carry out necessary adaptions with regard to structure and processes.

The strategic orientation – in what direction we are going to develop in the long run - is part of this close exchange. In this respect, it is important that the supplier gives us an open feedback what he expects from us. Feedback and criticism at eye level will help us to improve again and again.