Digitalisation at HORSCH

By means of digital systems farms and companies can make their processes more efficient and more transparent. But for HORSCH it mainly is about creating a benefit for the customers and the partners. A central step on this path is the digitalisation of processes within the company, but also outside the company. Philipp Horsch together with Maximilian Aurbach (Sales Support) and Bianca Pflanz (Process Management Service & Parts) explains what digitalisation looks like at HORSCH.

terraHORSCH: What does digitalisation mean for HORSCH?

Philipp Horsch: For HORSCH digitalisation is not a question of the business model, we want to create a benefit for our customers and our partners.

This is why the direction is perfectly obvious: our objective it not to earn money. We want to place digital systems at the disposal of the farmer and the dealer – as far as possible free of charge – that bring about a benefit and an added value. We want to simplify and interlink the course of operations so that the farmers can save time and money. In case of particularly high expenses on our part we at best want to have these expenses covered. This means in detail: We want to tackle processes and other topics to simplify and improve them for our customers and partners. But to achieve this objective we, of course, have to focus on digitalisation also with regard to internal processes.

This is why we divide the digital topics into two key aspects: on the one hand the internal sector and on the other hand the external sector.

terraHORSCH: What does the external digitalisation look like?

Philipp Horsch: With regard to the external digitalisation the focus is on the dealer and the farmer, thus our partners. The objective of the external strategy is to simplify the processes between manufacturer, dealer and customer, but also the processes in the agricultural farms. In this respect we mainly want to provide digital solutions to simplify and improve topics like data, communication and efficiency. Service and sales topics are also part of this.

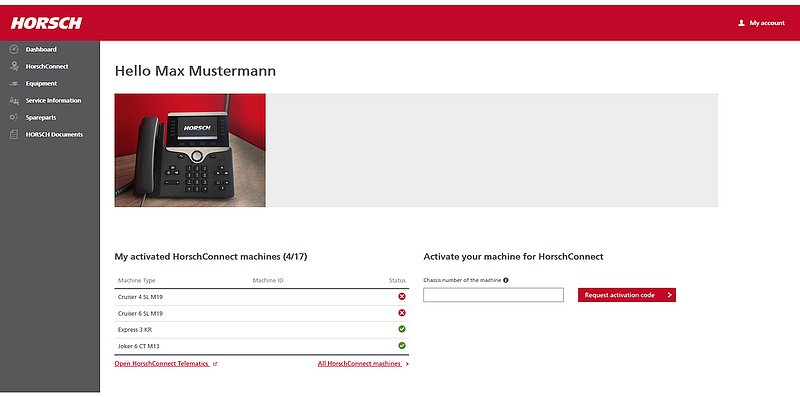

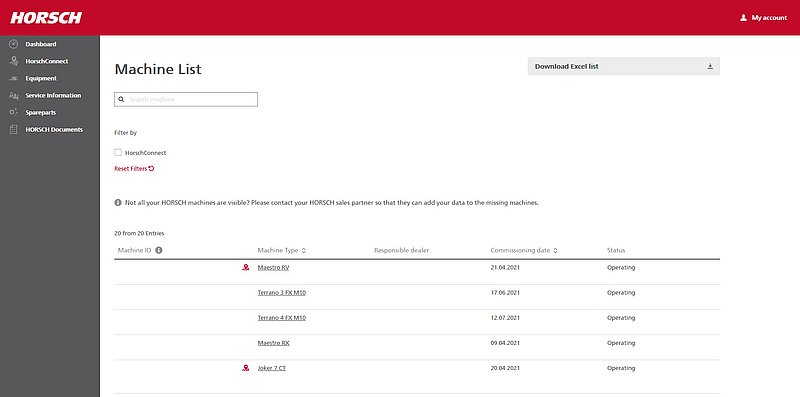

Maximilian Aurbach: This is exactly where the HORSCH Portal comes in. Previously, the HORSCH Portal was our service portal. Within the scope of our digitalisation activities, we are currently rebuilding it to a general HORSCH Portal. In the future, it will include for example a configurator, product information and other data that according to our digitalisation strategy are to support the dealer and the farmers in their everyday working life.

Bianca Pflanz: In general, you can describe the HORSCH Portal as an entry, exchange and communication platform with the outside. In the future, the Portal is where the exchange is to take place to take the co-operation to a digital level. For customers and dealers, it is to be the entry into the world of HORSCH. This, of course, includes challenges like the cleaning of master data and the changing of work processes. For a lot of information that can be found in the HORSCH Portal come for example from our ERP system.

Maximilian Aurbach: As we have already mentioned, in the future we want to place the HORSCH Portal at the disposal of the farmers. With the introduction of HorschConnect the farmer is provided with numerous opportunities. The future topics, thus, will be for example remote maintenance, software updates, but also the communication between driver and machine. In this respect we are constantly looking for new approaches.

Bianca Pflanz: Moreover, in the HORSCH Portal the customer will be able to access his machine history and service information. The objective is an increased transparency for the farmer and that the farmer is more and more provided with information in a digital format.

Maximilian Aurbach: We provide the possibility to access their own machine from anywhere in the world, to read out and analyse different farm parameters. We have lots of ideas what we can show the customer and how. And we will specify them step by step and put them into practice.

Philipp Horsch: It was and is not our objective to gather data and make the customer transparent. Our focus definitely is on ease of work, benefit and efficiency etc. Of course, to do so we need some data but only within the scope of what really brings a benefit. For us, digitalisation does not mean to get as much customer data as possible to make him transparent. Far from it. We, too, have to learn where the balance is – together with our customers. But as I have mentioned at the beginning: for us, it is not about business models. And this is why the focus is not on data, but on the ease of work and the communication it brings about.

terraHORSCH:What about the internal digitalisation topics?

Philipp Horsch: We want to digitalise all internal process within the company to the greatest possible extent. This concerns the departments R & D, production, sales, service etc. There are, of course, touch points with the external topics.

A rather important one is the PLM (Product Lifecycle Management) system. It is the basis that allows for interlinking and connecting a lot of things in the first place. The topics are linked to the PLM system as this is where the data is provided. What is important is the so-called Single Source of Truth, i.e. that there is only one spot in the company where you can find information. There may only be one single source for all data. This is the only way to avoid that information is stored in different locations as this would make it extremely difficult to keep them up-to-date.

Based on the PLM we are able to automate various processes like for example Portal processes, configurator, 3-D parts catalogue or the linking of the provision of information with the individual machine of the farmer.

Another topic we are working on are the first AI-based processes. First and foremost, we want to derive automation respectively automated processes from the data we have in our system. For example, in the purchasing sector. Our purchasing department is using AI algorithms for example to classify parts which makes calculations much easier. Thus, the objective is: if for example in the sheet metal sector new parts are designed, by using an AI it will be possible to calculate the prices most exactly and in a fully automated way and then also order these parts in an automated way. These AI topics are about the bulk processing of data which we can use to get new insights and derive processes.

terraHORSCH: What would this be like in the production sector?

Philipp Horsch: In the production sector we also pursue automation topics, for example with the supply chain, i.e. the production and supply chain process. Due to a comprehensive linking system, machines, storage systems etc exchange information. SAP also is an important part of it. We are talking about classics like the HubUnit plant which assembles automatedly but also about batch tracking, ease of work, facilitation of processes, documentation, quality monitoring etc. Thus, you achieve complete transparency along the whole supply chain. You can retrace everything from the supplier to the final product as it is documented, and you can identity optimisation potential and minimise process errors.

terraHORSCH: What are the challenges for HORSCH with regard to digitalisation?

Philipp Horsch: One challenge is that considering the DNA of our company digitalisation is not our core competence. It simply has nothing to do with practical farming. There are quite a lot of new topics we still have to familiarise with. With regard to digitalisation, in the past years we rather focussed on products, machines and other topics – this surely is also due to our roots.

Frankly speaking, I think this is the reason why we have a lot of catching up to do compared to other companies, especially with regard to the processes towards our dealers. In this respect we lag behind a little bit. But as you can see, we are dealing with it, and we want to make up leeway. In this respect we benefit considerably from our test mentality. We are not afraid of just trying new things. A good example is our D-LAB program. We started to look for digital-oriented employees in our company and now we have assembled a group from the different departments. They work on new ideas and develop new digitalisation steps. They examine what might fit where, what can be put into practice, what could be helpful. And they have the freedom to test these ideas. Thus, our experience grows, and we can assess what we need and what we can put into practice.