System comparison AirVac and AirSpeed

For two years the metering generations AirVac and AirSpeed have been working successfully in the universal single grain seed drill HORSCH Maestro. Two farmers tell us how they prove themselves in practice.

In addition to an excellent accuracy with regard to the placement of the grain, both metering systems excel due to their particular accuracy for all crops and all grain sizes. Moreover, the handling is very simple, and it is extremely user-friendly for example when changing between crops. Both metering devices are used in almost all markets.

Having two different singulation systems in the product range you can better adapt to the agronomic differences of the individual markets. Finally, beside precision and operational reliability what mainly counts are optimum populations and the maintaining and benefitting from the optimum sowing window. The next two examples will show how different the requirements of the customer respectively the sites are.

The AirVac system

Sowing in humid respectively wet conditions is typical for South America especially in the spring for the spring crop. What is important to know is what the cultivation practice in Brazil, more precisely in the soya regions in Mato Grosso and Mato Grosso do sul, is like: Soybeans mainly are sown as the first of two crops per year in spring. The second crop often is maize or a catch crop/greening.

This also is the farming strategy of Renato Duch in the Federal State of Mato Grosso do sul. The sowing year starts end of September with soybeans. At this time the soils are well saturated with water and because of additional rainfall while sowing he has to sow in wet conditions. Together with the high temperatures and intensive solar radiation these, however, are excellent conditions for the development of the soybean. Direct seeding is the preferred system for sowing soya and also maize. Because of the high annual rainfall, it is particularly important to cover the soil with harvest residues respectively catch crops.

With special front tools the machine has to work through a layer of organic matter that serves as a protection against erosion. Under this partly very thick layer the seed furrow is prepared with cutting discs or disc-tine combinations. Then the AirVac metering device is used to sow directly into the open slot. The operational speed normally amounts to 8 or 9 km/h to avoid creating an increased buoyancy of the organic matter. They do not even stop sowing when it rains.

In the conditions described above the AirVac metering device can show its advantages. The simple adjustment per crop and the uncomplicated changing between soya and maize are very important features.

To explain why the AirVac metering device is particularly suitable for wet sowing conditions we have to take a look at the functional principle:

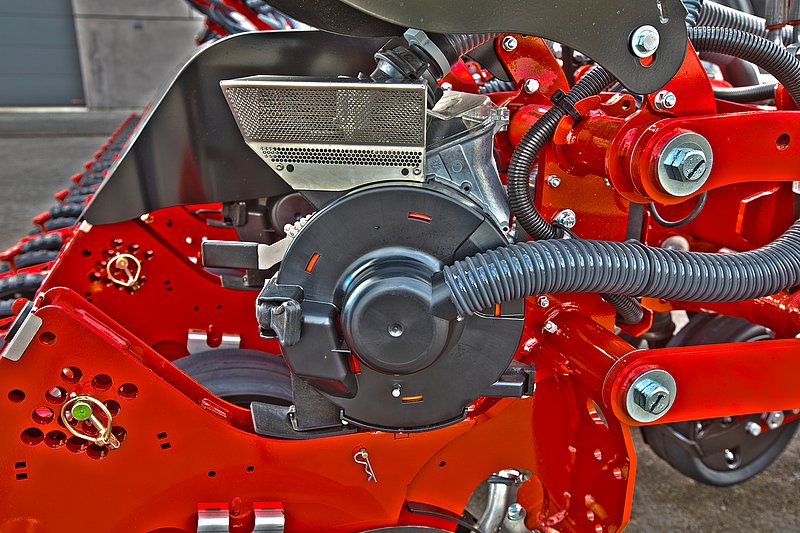

There is a vacuum in the metering housing of the AirVac metering device. Due to this vacuum the grains are sucked to the metering disc. The universal singulator guarantees that double seed on the disc is avoided, and it does not require any additional adjustment. In the release section the vacuum is interrupted, and the grains are falling freely through a specially optimized fall tube into the seed furrow. Thus, the AirVac metering device can be used with or without a catching roller in the furrow.

When working in slightly wet or rather dry conditions and with high operational speeds – in this case up to 12 km/h, the catching roller guarantees that the grains are immediately fixed in the seed furrow and cannot roll away. In addition, the grain is pressed into the seed furrow and thus gets an optimum connection with the soil water to guarantee a quick and regular emergence. If the sowing conditions, however, are very wet, you can work without a catching roller to avoid for example that the grains pick up on the roller. In this condition, the connection to humidity still is guaranteed. The catching roller can be added or removed very easily.

Renato Duch, Duch Group

“On our farm we use machines with the old metering device and with the new AirVac metering device. Both metering systems do an excellent job. The distribution has already been good and even has improved. The AirVac system is simpler, and it works well.

The old metering device did an excellent job. And AirVac brought further improvements along, especially with regard to the adaption to seed and sowing conditions.

The main difference I see is that the adjustment has been improved considerably. For example, the feed slide for seed now can be adjusted from the outside without having to open the metering device. And you do no longer have to add metal washers when changing the perforated discs in the singulator. It now can be used universally, and it works extremely precisely. Moreover, the visor for the seed was improved. Now you can better see the grains when adjusting the metering device.

These are details that facilitate the tasks of the user, the adjustments, the maintenance, and the daily routine.

We kept up our sowing speed because we think it is ideal. We sow with 9 km/h and the metering unit achieved an excellent distribution.”

The AirSpeed system

For dry black earth fields, you find them for example in the Ukraine, the optimum sowing windows are the basis for high yields, especially when sowing maize. Sowing normally starts as soon as there is soil temperature of min. 8 °C in the seed horizon. At this time, the soils usually are well filled with water but have already dried off on the surface, The objective is to sow all the fields perfectly in the shortest possible time to make sure that there is enough germination water for a high emergence. In this respect, the high efficiency of the AirSpeed metering device is a real asset.

Basically, the singulation of the grains works according to the same principle and with the same components as the AirVac system. However, the grains are pressed to the metering disc with overpressure and then actively shot into the seed furrow by means of an air current in a shoot pipe. We have already described this metering principle in detail in the terraHORSCH issue 20/2020.

An advantage is that the active grain transport allows for a very high operational speed while the placement accuracy remains constant. In practice, the speed usually ranges between 13 and 15 km/h. In good soil and sowing conditions higher speeds are possible, e.g. 16 to 18 km/h.

Kostiantyn Shytiuk, head of production of the agricultural holding Kernel in the Ukraine confirms this: “With a total of 57 Maestros we sow approx. 184,000 hectares of maize and sunflowers per season. We are already working with eight new Maestro 24 SX. When sowing maize with these machines we used the AirSpeed system at an average operational speed of 18 km/h. With 18 m working width and good logistics for seed and fertiliser filling we were able to sow up to 430 ha a day in shifts.

When sowing sunflowers, too, we achieved an enormous daily output with an average working speed of 16 km/h. The accuracy range of the AirSpeed system was excellent with a variation coefficient of 14 % to 20 %. With the Maestro 24 SX we can use the relatively short sowing windows in the Ukraine to full capacity. We finished sowing before the soils dried off too much.”

With the AirVac and AirSpeed systems the HORSCH Maestros can be adapted optimally to the individual requirements of the respective site.