HorschConnect – advantages through digitalisation

Agricultural engineering gets more and more interconnected. Machines can be controlled with the smartphone. At HORSCH, too, the developments with HorschConnect are advancing. Read the interview to learn how it all started, what the current developments are and what the future will bring with regard to digitalisation and connectivity.

terraHORSCH: How did HorschConnect start? What is HORSCH’s idea behind it?

Matthias Spork: With HorschConnect we pursue the vision to record and process telemetry data as well as to allow for controlling the machine via smartphone. We want to make HorschConnect available on all our machines and create new digital options in agriculture. For our customers, we thus generate an additional benefit: from the current position and speed of the machine to detailed information like error messages.

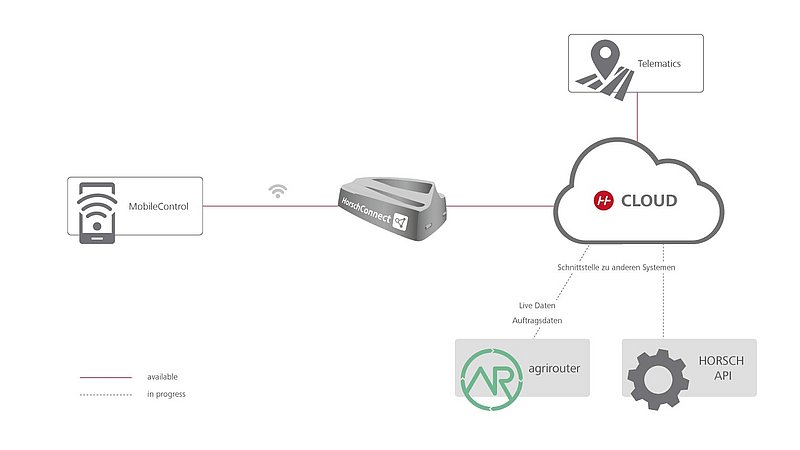

Theo Leeb: HorschConnect combines all developments and functions with regard to digitalisation, e.g. the HorschConnect Telematics Portal or the MobileControl app.

Theresa Schmidmeier: When we started the project, we ourselves did not know what the result would be. Our focus was on creating a base for everyone with the objective to make the data exchange as efficient as possible, to facilitate work processes and to improve the flow of information. It turned out that especially in the digital sector you have to react very quickly and specifically as the different markets always have quite different requirements. A lot of our customers more and more want to monitor their working quality, others want an error control or a fleet management. In a world where we are used to have a vacuum cleaning robot work while we are at work and to control it via an app, our customers, too, want to control their machines via an app respectively the smartphone.

terraHORSCH: Are there different groups of customers and what are the different requirements?

Matthias Spork: Yes, there are large farms with an increased focus on fleet management but also smaller farms that attach more importance to topics like automated documentation or traceability. With MobileControl our customers can quite concretely and immediately do something at their machine. HorschConnect and Telematics has been optimised for customers with one machine as well as for large farms with several machines. And it works excellently. You don’t need an initial training. Telematics has been designed in such a way that you can get going immediately. In addition to the detailed data of the individual machines, the customers with ten or twenty machines also see the essential data at one glance by means for example of the fleet dashboards and thus profit from an enormous benefit.

terraHORSCH: What do the machines need to be able to use HorschConnect?

Matthias Spork: The basis is the connection to the internet via the so-called SmartCan. This hardware solution is mounted directly at the machine and can go online automatically via LTE. With a smartphone, too, you can quite simply connect to the WLAN hotspot and use MobileControl, i.e. near-field applications like for example calibration, nozzle test, row test etc. For Telematics, the customer can activate the machine with only a few steps himself, the dealer, of course, can also support him in this respect. It’s only after that that position-related data are transferred to the HORSCH servers and you can then use the automated documentation as well as analyse machine data and error messages. An integrated memory card guarantees that no data is lost if there once is no mobile network coverage.

terraHORSCH: What is currently possible with HorschConnect? For which machines is it available?

Matthias Spork: HorschConnect is available for all our machine types – from seed drills and single grain seed drills to the crop care sprayers. A lot of machine types are equipped with it as standard, e.g. the self-propelled sprayers or the larger Maestros. For all other machines, HorschConnect is available as an option, e.g for the Pronto or the Sprinter. Moreover, all features can be retrofitted to most of the machines.

Theresa Schmidmeier: Currently we are a little bit Maestro-heavy. But this is due to the fact that we started the development of HorschConnect with the Maestro. But by now the functions are available for all product families - whether the telemetry features or MobileControl. It definitely is a product that is relevant for all product ranges. The design is always the same, but the functions in the telemetry portal can differ depending on the type of machine and the software version. The functional range is complemented and developed further continuously.

Some applications make sense for all product groups, e.g. the documentation of operational speeds or application rates as well as the visualisation of all (error) messages in the portal. Of course, the monitoring of the machine performance (e.g. hectare counter, operational hours and capacity utilisation), too, does not depend on the machine type.

But there also are individual functionalities for every machine sector:

In the crop care sector, you can for example see the selected nozzle profile and how the sprayer worked with which target area distance and within which pressure range. The nozzle status, too, is transferred into the map view, i.e. the active nozzles respectively errors that might currently occur at individual nozzles/sections.

For the Maestro range, in addition to the basic data, the singulation quality is particularly relevant to the user. Thus, by means of the telemetry portal he can retrace the variation coefficient of the machine respectively the share of gaps or double spots in a certain area of the field.

In the tillage sector there already are first approaches, e.g. with regard to area calculation and detection.

terraHORSCH: How does HorschConnect Telematics work?

Theresa Schmidmeier: HorschConnect Telematics allows for reviewing machine data and for analysing the data to record and adapt the work quality of the machine. Moreover, an automated documentation is possible. We work with farms that attach more importance to the performance of the machine as well as with farms with several machines that want to know what the machine currently does and how it works. What all have in common: they are demanding – and rightly so. And this is our basis for example in the service sector. We want to support our customers specifically and proactively, e.g. by a further analysis of error messages or by supporting them with regard to the configuration. We are also working on solutions where the service can access the terminal and the machine remotely. Thus, we can provide a targeted support.

Theo Leeb: The service topic is extremely important, and it is and will remain a quality characteristic. In my opinion, it is the key. Those who in addition to a good machine can provide the best service will make the deal. Basically, the technological possibilities increase rapidly. Just think of the most different sensor technologies, camera systems, artificial intelligence etc. I.e. the machines become more and more complex. The more important is a quick and straightforward support for our dealers and customers. To be able to guarantee an optimum service for the customer, it will one day be vital to have the option of a direct access to the machine and the machine data. I think that topics like service, connectivity, updateability, access to the machine are highly important to manage this complexity in the first place.

Via the machine access we also can deploy updates to the machine. It is not necessary that one of our HORSCH employees visits the customer and blocks the machine for three hours. It can simply be done overnight.

Matthias Spork: Prospectively, the system has the big advantage that our updates are carried out completely automatically. As soon as the machine is at work, the SmartCan is online and updates automatically via the internet. The MobileControl app is updated via the well-known Apple and Google app stores to make sure that everything works together in an optimum way. The machine is delivered with a SIM card – virtually “ready to use“. I.e. the customer does not have to bear any additional costs for this service.

terraHORSCH: What about the access of machine data especially regarding the topic of data protection?

Theresa Schmidmeier: This is a topic we take very seriously. With regard to the question “Who sees what and at what time” we have a clear strategy: Only the service or sales partners can review the machine data, if the customer has given his consent. At a certain point in time the customer explicitly has to confirm: “Yes, I want to use this system and I want that the data of the machine are transferred to HORSCH via my account”. The direct communication with MobileControl or the app function etc., of course, also work without an activation. And the data is not personalised, i.e. several users can access the machine data. This is particularly interesting for farms with several employees.

Matthias Spork: This consent can be given via a form that the customer signs together with the sales contract at the dealer. If, at that time, the customer still is uncertain what to do or wants to get further information, the customer can create an account under portal.horsch.com and activate the machine via our portal and the terminal himself. In this case, he also has to tick the obligatory boxes and he can decide if the service partner will be allowed to access the data or not.

It is only after this declaration of consent that the service partners can access the data of the machine. At the time of the machine activation the final customer can decide if the dealer will be allowed to see the machine data.

terraHORSCH: What is the benefit for the customer?

Theresa Schmidmeier: In addition to the functions we have already described, we are working on a lot of features our customers require. We will for example soon be able to send error messages as push notifications or provide field-specific key data. This helps to optimise processes or to increase efficiency as the displayed information is compressed to the essential or is sent directly to a smartphone.

We also noticed that there are countries that attach even more attention to details than Germany. Especially with regard to topics like the burden of proof or automated documentation for example in the crop care sector. This is the reason why a lot of customers want the sector of documentation or everything to do with office work to be automated and that some workload is taken off them to be able to concentrate on the actual work with the machine. We can facilitate work processes essentially and make the flow of information quicker and better. In the sector of error messages, too, we see an advantage for manufacturer and customer. No employee has to go to the customer to read out the error memory, and everyone can react proactively.

Theo Leeb: It is important that HorschConnect in the future is also compatible with other systems to offer the customers an utmost benefit. This is our digital strategy. We deliberately do not want exclusivity, i.e. no isolated application. The customers want to use the platform comprehensively and independent of a manufacturer. Our strategy is not to create dependency for our customers. On the contrary: It has been and it still is our deliberate decision to provide the customer with an added value which goes beyond any brand colour.

Theresa Schmidmeier: This is why the connection to the agrirouter as an interface to other systems was a deliberate decision. Thus, the data exchange between the platforms of different manufacturers becomes simple, safe and automated. The most important thing is that the customer keeps all data in hand. Via this system, application maps for example can be sent directly from the PC to the machine and back. I.e. we are completely autarkic from the hardware point of view when it comes to machine, tractor and other rigs. With regard to compatibility, interfaces etc. the more we enter into the market the more we notice that is important to have an open system and to give the customer the choice.

Matthias Spork: This is where in 2022 our focus is on. For there are so many digital topics respectively software. HorschConnect is another big step for our customers who already use digital systems and are digitally savvy. Also because it can easily be integrated into the already existing system landscape.

But HorschConnect is also ideal for farms that want to enter the world of digitalisation. Due to the simple and intuitive handling, it offers utmost transparency and does not require any previous knowledge.

Theo Leeb: We as a company also use HorschConnect. So we are professional users ourselves. At the beginning, we were really surprised which information we can get from the data – already in the prototype respectively in the development stage. There simply is an incredibly high potential in it.

terraHORSCH: What about the costs?

Theresa Schmidmeier: Of course, the development of the system, i.e. hardware and software, costs money. But we also have running costs for data transfer and data storage. We want to make it as easy as possible for our customers and only offer one bundle. Moreover, the use of the online services for the first two years is included when purchasing a new machine. The SIM card is also included and there are no additional costs for mobile services.

terraHORSCH: Where will the journey with HorschConnect be taking us?

Theo Leeb: In the future, not only steel and iron but software and electronic topics will more and more make the difference with regard to the quality of the machine. Let’s take a look beyond our own nose. In some sectors, it is common to place new functions at the disposal of the user in relatively short intervals overnight via an update “over the air”. This still is hard to imagine for the sector of agricultural engineering as in this case a service specialist has to go to the machine to deploy an update. Given the large number of machines we think twice if and which machines have to be updated. With HorschConnect the update will be carried out by the push of a button. This process changes the update frequency, and the costs are reduced, too. Another advantage is that in the future many features can be launched promptly and are then directly available for the machine and the customer. We do no longer accumulate everything until we visit the customer next time. Via the portal, it will also be possible to select the updates and features individually and to update them afterwards.

Matthias Spork: A lot of ideas for new functions develop while talking to our customers. One example is the possibility to plan the routes of the machines or the display of all error messages on the map. You can send your requirements and improvements any time to portal@horsch.com – we are looking forward to every e-mail.