Mechanical sowing technology pushed by innovation

Especially in small-structured regions mechanical sowing technology is quite common. With the Versa KR HORSCH offers an appropriate product in this sector. terraHORSCH talked to Kai-Christian Schramm from the product marketing and Maximilian Kandlbinder from the product management.

The name Versa is Latin and means “reverse”. It alludes to the fact that since the foundation of the company HORSCH exclusively relied on pneumatic metering systems. Just a quick reminder: HORSCH was the first company to build a pneumatic drill (PD 12). The seed drill range is now expanded to offer an optimum solution for the most different farm sizes and site conditions.

The rotary harrow is nothing fundamentally new, for on heavy or extremely changing sites it has its advantages due to a very regulated adaption of the seedbed preparation intensity when sowing.

“Especially in Southern Germany, where we actually come from, a lot of farms demand a lighter 3 meter seed drill below the Express 3 KR”, Kai-Christian Schramm from the HORSCH product marketing says. “But if we enter a segment that is new to us, we want to be particularly innovative”, his colleague Maximilian Kandlbinder adds. “The Versa KR definitely isn’t a low-budget machine but is to set standards in the mechanical seed drill sector.”

Working quality counts

So first of all, HORSCH took its time to examine the requirements of the farmers closely. Kai-Christian Schramm explains: “The customers all have similar requirements on precision when sowing. We noticed this when we worked with the pre-series machines. I can already tell you this much: We managed to convince a lot of farmers. A Versa KR for example is used at a mixed farm with a focus on livestock farming where arable farming is rather used to produce fodder components. In this case, a seed drill has to be simple, efficient and intuitive. The same is true for farms whose strategy to achieve a high marginal return is based on diversification. This is why they need a lot of flexibility, for example the possibility to work with different row spacings. And we must not forget that all farms constantly develop further regardless of the farm size. The typical markets are situated in Central and Eastern Europe. In general farmers attach major importance to work quality. For finally this is what guarantees the yield.“

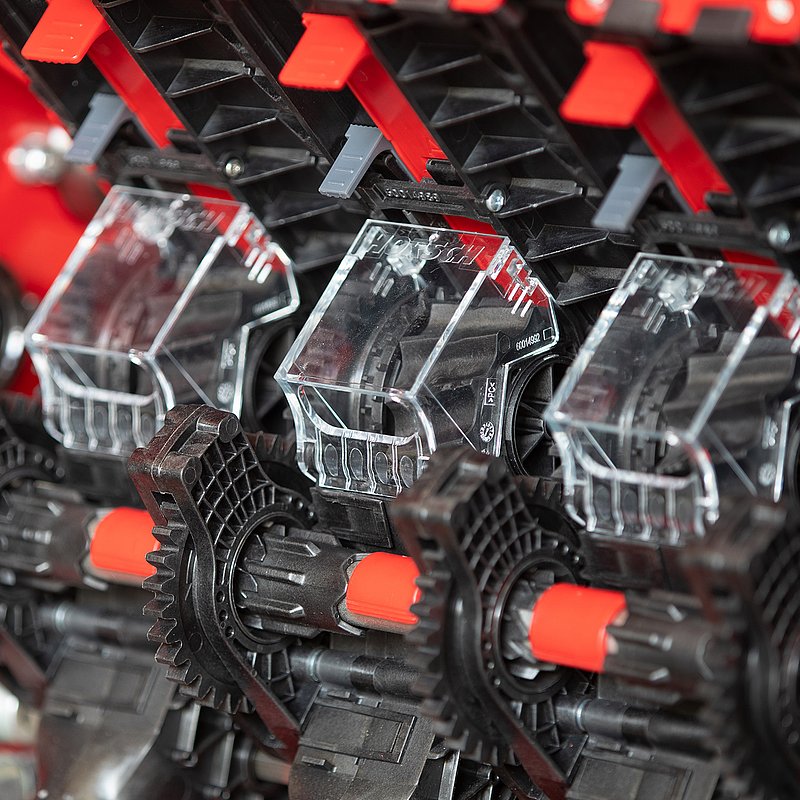

The core of the seed drill is the electrically driven metering system called SmartClip on the counter shaft. The metering devices are controlled individually. Thus, tramlines can be adjusted individually – without any tools. “With regard to row spacings, we are very flexible due to SmartClip. This is extraordinary in this machine category. 15, 30 or 45 cm are no problem at all, neither are 12.5, 25 and 37.5 cm”, Kai-Christian Schramm explains. The same is true for the tramline rhythm. This flexibility is particularly important for machine co-operatives or if the seed drill is rented out.

“The metering itself – depending on the seed - is adjusted by means of a stop valve between spacing wheel and cam wheel”, Maximilian Kandlbinder explains. “The metering wheel can be removed individually and without tools if it has to be checked or replaced. The Versa KR can handle the most different seeds and crops, especially rape, wheat, barley and legumes. The seed quantities so far range from 1.5 to 250 kg/ha. Lower and higher seed quantities for special crops or extremely high seed quantities are to follow next year.”

The Versa KR is ISOBUS-compatible as a standard. It is operated via the tractor terminal or the HORSCH Touch 800 terminal and allows for an individual setting of the display options. The view in the terminal for example can be customised. It is possible to sow by means of application maps with VariableRate over the whole or half of the working width. SectionControl is an important topic in our target market and even gets more and more important. Hardware and software are the latest generation from HORSCH. The I-Manager is only used in the Versa KR this way. The other machines will be equipped with it only step by step.”

The machine is completely operated from the left side of the machine. Sowing depth and coulter pressure can be adjusted quickly and easily with a monkey wrench.

Well-proven basis

The second core are the DuoDisc seed coulters. The double disc coulter that was specifically developed for the Versa line is based on the well-proven components of the TurboDisc seed coulters. “Thus, we achieve a precise and even seed placement, a perfect emergence and finally populations that are more than satisfying”, Kai-Christian Schramm says. “According to our experience, with our double disc coulter emergence is significantly more even than with a drag coulter.”

The capacity of the seed hopper amounts to 900 l. Optional attachments are available to expand the capacity to 1,200 l or 1,500 l. This guarantees efficiency.

The Versa 3 KR is based on the well-known rotary harrow Kredo. The 3-metre machine is equipped with ten rotors. There are two different packers: the tooth packer roller with a diameter of 64 cm is ideal for universal use. The load-bearing capacity is high what is favourable for the horsepower requirement and thus also for the fuel consumption. The trapeze ring packer has a diameter of 50 cm for heavy soils with a high punctual consolidation performance or of 60 cm for changing soils with high requirements on the load-bearing capacity. When choosing the tractor, it should be taken into account that the packers influence the weight of the whole machine significantly. The machine has been designed for tractors from 160 hp upwards which can handle a 3 tonne seed combination.

The rotary harrow can, of course, also be used solo. In this case the seed unit is uncoupled via four fixing points. Parking supports are part of the standard delivery.

“With regard to the equipment options we are not yet finished by far”, Maximilian Kandlbinder informs. “There soon will be some more options. After all we have gathered enough experiences with large technology which we can also use in this sector to stand out from our competitors. One example is the use of two components for undersown crops or underground fertilisation. I could perfectly imagine these fields of application for the Versa KR. Or also the sector of seed flow monitoring.“

The mechanical seed drill is available as of this season. However, the first machines were sold out very quickly. Moreover, a lot of dealers bought demonstration machines for the autumn season 2021. Like the Express and the Kredo, the Versa is built in Ronneburg.

Kai-Christian Schramm is happy about the enormous interest in the Versa KR. “We introduced the Versa KR on the occasion of our online trainings in spring”, he says. “The Versa KR attracted a great deal of attention in many markets. And even the markets where rotary harrow combinations have not played a major role so far asked about the machine at the end of the training. The Versa KR really is technology of tomorrow.”