![[Translate to englisch:] Maestro SW 24 [Translate to englisch:] terraHORSCH 21-2020: Maestro SW 24](/fileadmin/_processed_/2/7/csm_14-17_Maestro_24_SW_Product_Image_ed6e88f406.jpg)

An agri-group of superlatives

The figures speak for themselves: On 515,000 hectares the Ukrainian farm Kernel produces cereals as well as oilseeds with utmost precision and Precision Farming with a total yield of more than 3.2 million tons. And the HORSCH Maestro single grain technology plays an important role.

Soon the first HORSCH Maestro 24 SX single grain seed drills will work on the Kernel farm in the Ukraine. They proved their advantages during demonstrations and extensive tests. And 50 Maestros 24 SW already are the key machines for sowing sunflowers and maize. But wait a minute: 50 24-row single grain seed drills? What kind of farm is that? terraHORSCH presents this company.

Kernel is one of the largest farms in the Ukraine. Due to its size its importance is international. The shares of the company are traded at the stock exchange in Warsaw. The turnover of the business year 2019/2020 amounted to 4.1 billion Dollar. Kernel employees about 12,000 people over all sectors of the company and its mission statement is: “It is our objective to release the potential of the Ukrainian food production to feed the growing world population in a sustainable way.”

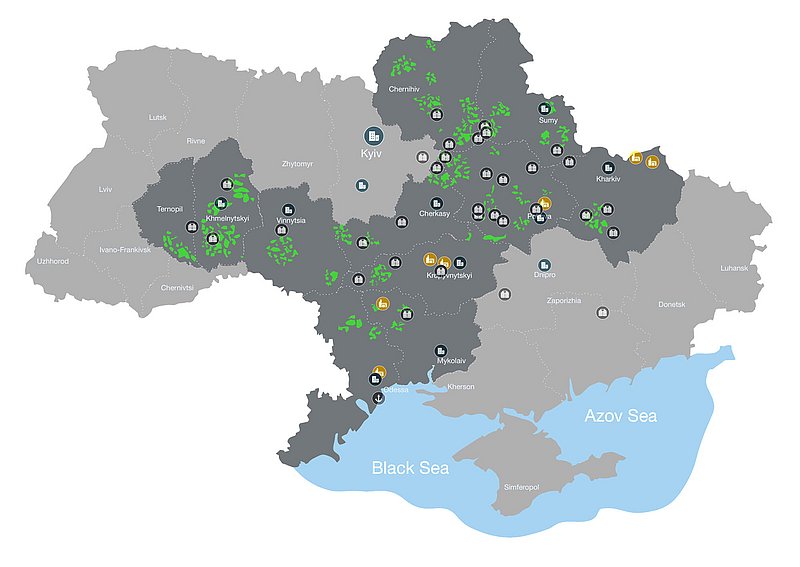

In the arable farming sector, there are 515,000 hectares of land that are spread over the whole country. It thus, of course, does not make sense to give exact particulars about soil points and soil quality. The spectrum ranges from average to very good soils. 3.2 million tons of cereals and oilseeds are harvested on the rented fields making Kernel the largest agricultural producer in the Ukraine. About 6,000 other farmers supply Kernel with 3 million tons of sunflower seeds and 5.1 million tons of cereals. The main crops are maize, wheat and sunflowers.

These products then move directly into Kernel‘s second business sector “Trade and Infrastructure“. The capacity of the silos amounts to 2.4 million tons, the plants are spread over the Ukraine in a decentralised way.

7.9 million tons of cereals and oilseeds are exported. Strategic forward contracts allow for very tight periods of time between the own harvest or the delivery from other farms and the resale. Everything is hedged against price fluctuations. Their own train fleet with 3,443 cereal wagons guarantees a smooth flow of goods from the inland silos to the ports. Kernel operates two deep water terminals in Chornomorsk with an annual handling capacity of 8.8 million tons. Thus, the company owns the largest, private train fleet and the largest silo capacity of the whole country. And it also is the largest cereals exporter of the Ukraine with a share of 14 % in national exports.

The main target markets for the 7.9 million tons of exported cereals are Asia with 44 %, Europe with 35 % and the Middle East with 16 %.

Sunflower oil is the second line of business of the Kernel group. It is quite interesting to know the historic background why the Ukraine is such a large producer of sunflower oil.

More than 20 years ago the country started to strongly promote the production of oil directly in the country with an export tax on sunflower seeds. It was more economic for all producers to produce the oil themselves instead of exporting the seeds. The result was that with about 7.4 million tons of sunflower oil the Ukraine today is the largest producer worldwide. It is followed by Russia with 5.7 million tons, the EU with 3.7 million tons and Argentina with 1.2 million tons of sunflower oil. The worldwide production amounts to about 22 million tons. Kernel’s eight oil mills have a processing capacity of 3.5 million tons of sunflower seeds per year. To give you a rough idea: 1,000 kg of sunflower seeds in average yield 440 kg of oil, 390 kg of oil cake and 160 kg of sunflower husks.

About 145 million litres of oil are filled directly into bottles and prepared for the export in the port terminal und for being sold in the Ukraine. In addition, 1.4 million tons of sunflower oil cake are delivered to the port for export.

This means that Kernel is the largest producer (7 % of the global production) and the largest exporter (15 % of the quantity that is traded internationally) of sunflower oil worldwide. 29 % of the 1.5 million litres go to Europe, 24 % to the Iraq, 23 % to India and 16 % to China.

Precision and digitalisation

A farm of this size can only be run efficiently with a high degree of digitalisation. For maximum performance in farming you need solid and absolutely precise machines which excel due to simple handling, reliability and high area output with precise seed placement. This is where some years ago HORSCH came in. Already since 2009 HORSCH has been supplying Kernel with the compact disc harrow Joker RT and the universal seed drill Pronto DC PPF.

The experiences with these machines were so positive that in 2014 Kernel decided to use the Maestro SW for the single grain sowing of maize and sunflowers. In the meantime, about 50 machines of the Maestro 24 SW line are used on 515,000 hectares of arable land.

Since then, the agronomists and the farm managers of the different farms have been using the technology to its limits. Every machine sows about 3,500 hectares per year. The area output, however, is achieved in only very few days as the company tries to make use of the optimum sowing windows and this always requires maximum performance.

And this is where digitalisation comes in. The company analyses all data of every single machine to the last detail: settings, operational speeds, gaps, placement quality and accuracy. The data of the machine which performs best are used to optimise all the other machines. “Kernel’s objective is to allow for efficient sowing at the ideal time“, Johannes Kluth, the managing director of HORSCH Ukraine explains. “At such a large farm we can impressively prove the efficiency of our machines. Everything we tell you in the leaflets or our website, is demonstrated here during the season live in the field“, Kluth says.

Of course, such a good co-operation requires personal contact. There are regular meetings in the company headquarters in Kiev. On this occasion, HORSCH and Kernel inform each other about innovations and co-ordinate their strategies. New products and equipment versions are presented, they discuss how to go on.

The practical work then is shifted into the regions to the individual farms.

The specialists of the HORSCH sales and service team are always available. Basically, the complete initial use, warranty and service for the machines is carried out by sales partners on site. The trainings for the Kernel drivers and engineers are an important element and crucial for the success in such large structures. For many years practical trainings have been held in winter where the participants are kept up to date.

At the end of the training every driver gets a certificate that attests that he is a trained and skilled professional expert. Only these drivers are allowed to drive a tractor during the season. This is a win-win situation, for the tractor drivers, thus, are able to make use of the maximum capacity of the machines.

“This co-operation is a perfect example for the triangular relationship between manufacturer, dealer and customer – regardless of the size. We do not have a top-down relationship where our information goes to the dealer and only the dealer communicates with the customer. This is what makes us special. We talk to the customer and the dealer about requirements and objectives and thus we can provide the perfect solution for the respective farm“, Johannes Kluth, the managing director of HORSCH Ukraine says.

Such strategic meetings were the reason that the first Maestro SX are now used at Kernel. After the Kernel responsibles visited the HORSCH company headquarters in Schwandorf, the first discussions with regard to the new Maestro 24 SX started at the Agritechnica 2019.

Three factors were important for the choice: the excellent experiences with the Maestro 24 SW and its solid and reliable work in all conditions, the new high-speed shooting metering system and the telemetric system.

In the spring season the Maestro performed absolutely convincingly due to its precise metering system even at high operational speeds. An important point was the constant performance even though the seed quality had not been optimum. For it is clear that on 515,000 hectares you will not be able to always dispose of only perfectly calibrated seed.

The telemetry via HorschConnect makes the actual sowing process absolutely transparent. Especially due to the real time control you can check anytime how efficiently and powerfully the individual machines are working. And if four machines out of five for example perform excellently and one does not, the responsible people can intervene immediately. This way, of course, you can react much faster than if you do not see until the emergence of the plant that there has been a problem.

Summary...

“Due to telemetry and the precise metering system of the Maestro 24 SX we can integrate this seed drill easily and completely into our Precision Farming system“, the deputy managing director of “Kernel Agribusiness“, Konstantin Schitiuk, comments enthusiastically.

In practice it means that due to the new Maestro SX and in optimum conditions Kernel was able to achieve an additional performance of up to 25 % compared to the average of all Maestros 24 SW working on the farm. This increase is the result of the precise metering at high speeds. For an optimum placement liquid fertiliser is applied. The hopper size of the Maestros is an additional argument for their efficiency. The capacity of 9,000 litres can either be ordered with a partition of 2,000/7,000 (seed/fertiliser) or with a partition of 4,000/5,000.

In HorschConnect the machines are displayed in a clearly laid-out way with a user-friendly visual design.

Efficiency and power also are the crucial criteria for other machines that are currently tested by Kernel.

The knife roller Cultro 12 TC stands for an enormous area output with low power requirement and operational speeds up to 20 km/h. When working in the field the weight of the machine completely rests on the knife roller. The Cultro is ideal for crushing catch crop populations in spring or for an ultra-shallow stubble cultivation for example in sunflowers and maize. Kernel mainly uses the machine for crushing sunflower stems after threshing. After the harvest, the stems often still are 1.5 m long, after the first pass they are cut down to a maximum of 30 cm.

In the plant protection sector, too, Kernel gathers first experiences with technology from HORSCH. The Leeb VL is a new self-propelled sprayer model based on the new Leeb PT that was presented at the Agritechnica 2019. In the last issue of terraHORSCH Theo Leeb talked in detail about the advantages of the Leeb VL.

The new self-propelled sprayer line VL (variable large) is equipped with telescopic axles, a new individual wheel suspension and a variably adjustable track adjustment. At the VL, the latter is available in two versions – between 2.60 and 3.50 m and from 3 to 4 m. Both can be equipped with an optional height adjustment of up to 2 m. Due to the intensive cultivation of sunflowers and maize Kernel rarely uses trailed sprayers. For these crops, the clearance is crucial. The tank capacity of 6,000 l and 8,000 l thus guarantees utmost efficiency in sunflowers and maize.