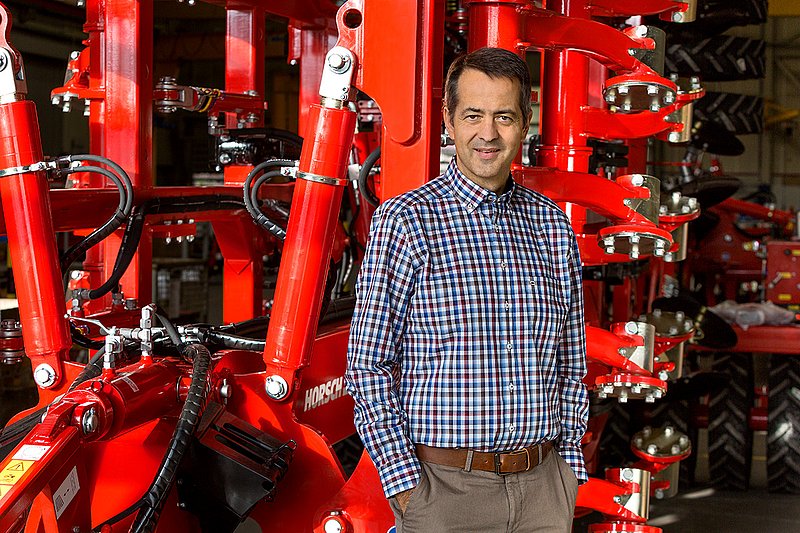

Focus on the customer

HORSCH’s particular focus is always on the customer. Philipp Horsch explains to terraHORSCH what this exactly means and how much influence the customer really has.

terraHORSCH: What does the term “customer focus” mean to you?

Philipp Horsch: It means that in every part of our company the customer always is the key. This also refers to internal processes. It is our objective to always question our decisions and make sure that what we do really helps the customer. This can be little things like for example to rethink the availability of our service call centre or the opening hours of the company. We know that especially when sowing or during the harvest the customer needs us 24/7. It is the supreme discipline to put the customer focus in the centre of attention of all divisions and of all heads of the company. We constantly work on our processes and on getting better.

Can you specify this with regard to the technical features of the HORSCH products?

Philipp Horsch: In the past centuries we tackled a lot of topics and partly even were ahead of the market. For example, already in the middle of the 1990s we started to deal with contact fertilisation and fertilisation below the seed horizon. Moreover, at that time, we began to think about how machines could be able to apply several components. Today, we still live on the numerous developments of that time. In this respect, I think for example of our metering system. The standard electric drive at that time was completely new in our sector. Furthermore, we were the first to do without an agitator shaft at the metering device and to have a system that was suitable for fertiliser as a standard. The metering system still is very successful and quite a large number works out in the fields every day. The great potential of the fertilisation topic already showed at that time. Over the years, our focus was to work on the efficiency of fertilisation – in close co-operation with our customers. And we developed quite a lot of things together with them. The best proof is that in the meantime all tillage tools and all seed drills are suitable for applying fertiliser. Our key focus has always been on the benefit for the farmer and the environment. The protection of resources, the increase of efficiency and the maintenance of the health of the plants are very important aspects.

Every now and then machines developed from the co-operation with the customers. Which machine comes to your mind when you think of the topic of fertilisation?

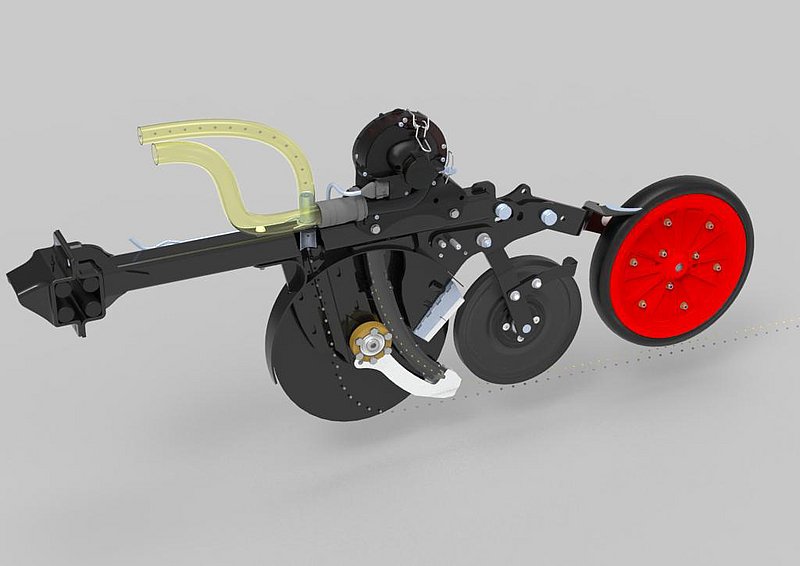

Philipp Horsch: Some years ago, the HORSCH Focus came into being as a result of all the research and discussions about the topic fertilisation. And this quickly confirmed that there is an enormous potential in working together with our customers. During the development of the HORSCH Focus we were also strongly influenced by the StripTill topic. Already before, we had dealt intensely with StripTill sowing for maize and had also carried out tests on our own fields. We soon realised that the targeted loosening and the fertilisation aspect are the main advantages of this method. The combination of StripTill and sowing in one machine then resulted in the HORSCH Focus. In the meantime, the HORSCH Focus has become one of the most important seed drills in the high-yield regions of Central and Eastern Europe. But during the development of the Focus we also noticed that it is not possible to put all of the customers’ wishes into practice.

What was the trigger that made you focus even more on the fertilisation topic?

Philipp Horsch: The origins of fertilisation in our company go back to the 1980s. At that time, we carried out first fertilisation tests with urea for the cultivation of rape and we noticed that contact fertilisation allowed for achieving an enormous effect with small quantities of fertiliser. Some years later we pushed this system even further with the Airseeder and the Duett coulters. We managed to apply even larger quantities without causing burns. Especially when sowing in the spring we observed significant effects. Today the trend again goes to not increasing the fertiliser quantities while sowing any further. The objective is to apply the fertiliser even more precisely directly at the grain. We deal with special questions about the topic of fertilisation which refer to individual sites. Multiple-component fertilisation also is a big and current subject that is getting more and more important. The requirements mainly are to regulate multiple components in a site-specific way – and all this for every single component. Some weeks ago, I was in Canada and had several interesting discussions with our customers over there about the future of farming. With regard to fertilisation the trend according to the Canadian farmers is towards fertilising with up to five components. This is a clear sign that farmers increasingly concentrate on the effect of individual fertiliser components. We as a manufacturer, of course, have to deal with this and include it in our future developments.

In your opinion, how can we manage to work even more precisely in the field?

Philipp Horsch: The question about more precision in the field becomes more and more important in all sectors. Our next step is called RowControl. It basically is about SectionControl for pneumatic seed drills to reduce overlap areas on the headlands – i.e. to be able to work more precisely. In this respect, we worked on quite a lot of topics, e.g. on segmented metering rotors and, as already mentioned, on our RowControl distribution head which allows for a real individual row switch-off for seed drills. If you take the solution one step further, we also have the option for double hopper machines to switch fertiliser on and off with pinpoint accuracy or to always switch the fertiliser off at the field boundaries. It is an open secret that we are working on a pneumatic fertiliser spreader. This spreader, too, will be equipped with this technology and, thus, precision in the boundary and overlap areas will increase significantly. But let’s get back to sowing once again: If crop populations are to be hoed, precision on or near the headlands is crucial. Areas that are sown over always cause problems for mechanical population care measures. Gaps always are a good location for weeds and grass weeds. If you sow with RowControl, you can avoid both problems.

What other topics are marked by the requirements of the customers?

Philipp Horsch: We are discussing the topic of the optimum seed depth regulation intensely with our customers and are exchanging experiences with them. The point is to improve the sowing depths in strongly varying soils. We are already testing some first approaches in the field. The tests we have carried out so far are based on soil maps. That is: we control the depth via application maps that have been prepared beforehand. The next step, of course, is to work out a closed loop system so that this process is carried out automatically. We already have some interesting ideas, e.g. a new sensor system that is able to identify the soil structure in the seedbed.

Another important topic is plant protection. Driven by new technologies our focus is completely on the benefit for our customers. With our BoomControl system for a precise boom control we still set standards all over the world – not only with regard to the quality of the application, but also with regard to the efficiency of the agent. Due to the increased demands of our customers we constantly extend the product range in the plant protection sector. With the new HORSCH Leeb AX we completed the range of trailed sprayers in the lower-capacity sector. At the moment, we are working on a large tandem sprayer to complete the range with larger capacity tanks. In the plant protection sector, we are putting new concepts into practice due to the feedback and assessment or the customers. The completely new platform in the self-propelled sprayer sector is an excellent example. On the one hand, the new Leeb PT will be equipped with state-ofthe-art components and technologies. On the other hand, we stick to our usual approach to open the doors to variety and to develop a whole platform of different self-propelled sprayers for various markets. Visit us at the Agritechnica to see more.

To what extent is it important for you to act in a market-specific way and what has this got to do with customer focus?

Philipp Horsch: It is part of our DNA that in all divisions and departments we deal with a lot of topics and deliberately encourage variety. Variety is a crucial part of our company and one of the most evident signs of a real customer focus. We do not offer our customers standard solutions, but we attach great importance to listening and responding individually to the requirements which are different all over the world. Moreover, we continue to work on the details of our already existing products.

How do you succeed in branding a new sector like the technology for mechanical population care with the HORSCH DNA right from the start?

Philipp Horsch: Mechanical weed control is nothing new and we have already been dealing with this subject for several years. With regard to the approach we, at first, always only deal with these topics on the side. Little by little we gain insights that make us look into this development more intensely. Right from the start it was clear for us that we would handle the topic of mechanical weed control ourselves. We did not want to buy a company from this sector. So our approach is a little bit different from some of our competitors. But this is the only way to make sure that the final product is marked by the HORSCH DNA. For such projects, we first concentrate on the ideas of the farmers, but also include our own ones. The influences from the outside plus the influences from the inside eventually add up to a clear picture. As soon as we reach this step, the remaining development process takes place very fast. We attach great importance to use our long-standing experiences and include them directly. For example with regard to topics like durability, frame design or frame stability we draw from a an ample pool of experiences. All this is completed by our agronomic experiences. In the sector of organic farming it is important that we include the experiences we gather on our own agricultural land. Moreover, a lot of excellent organic farmers who show initiative and provide valuable inputs accompany us. We as a company learn a lot along the way. In my opinion we all – farmers as well as manufacturers of agricultural machinery – will be facing exciting times in the future.